Hinge Type Conveyor

Structure

StructureTransport chips on a belt that connects pressed plates with rods.

Features

Although not suitable for sandy chips, this is a versatile chip conveyor that can deal with other general chips, materials and sizes.It is suitable for the use of coolant in a medium or lower quantity.

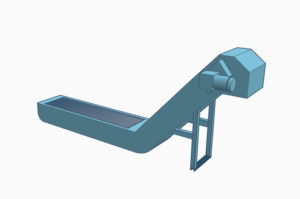

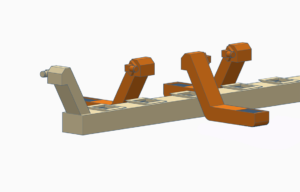

Scraper Conveyor

Structure

StructureChips received by the footplate of the conveyor are scratched and transported by a scraper bent at 90º or 120º.

Features

Although not suitable for long chips clinging to the scraper, this can deal with sandy and short chips. It is suitable for the use of coolant in a medium or lower quantity. Because of its simple structure, it can be manufactured at a comparatively low cost.

Magnetic Scraper Conveyor

Structure

StructureMagnet is paved under (outside) the footplate of a scraper conveyor so that chips in a liquid are adsorbed on the footplate, scraped and transported.

Features

Although not usable for long chips and those not aspirated onto magnet, this can deal with chips from short iron and casting.It is suitable for the use of coolant.

Scraper Conveyor With Rotary Filter Unit

Structure

StructureThis is a filtration conveyor in which a netted backwashing drum is built in the middle of a belt of a scraper conveyor.

Features

Our drums use unique stainless steel specially woven nets and are characterized by their strong property against damage. Copper nets are also available that work to prevent oily slime and have an antibacterial activity for coolant. They have been developed for processing aluminum that uses a lot of coolant solution.The mesh is selected usually from among #80 to #200 mesh based on the required filtration rate and precision.

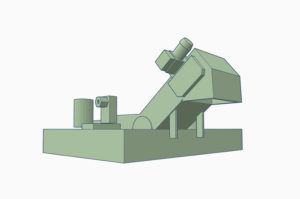

Shaftless Conveyor

Structure

This is a conveyor with a shaft driving a scraper belt installed outside the trough.

Features

Getting rid of a shaft from inside has resolved clinging of chips.This enables long chips to be transported on a scraper conveyor.

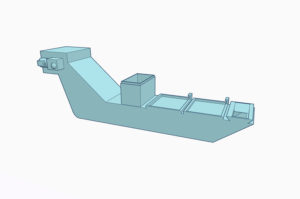

Two Stages Conveyor

Structure

StructureThis is a two-tier conveyor: arranging a backwashing conveyor under a hinge conveyor.

Features

The upper hinge conveyor receives and discharges long chips while the lower backwashing conveyor performs microfiltration. This allows for transportation of mix-up of short and long chips.

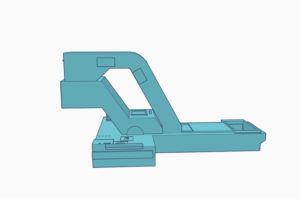

Scraper & Hinge Type Conveyor with Rotary Filter Unit

Structure

StructureHinge belts are laid out partially on the scraper belt of a backwashing drum filter conveyor to transport chips with the scraping power and holding power.

Features

This enables long chips and lumps of chips, the weakest point of a scraper conveyor, to be transported.

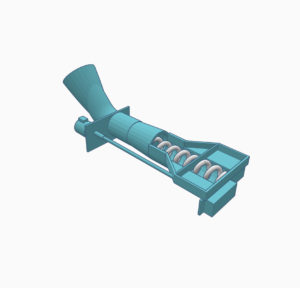

Coil Conveyor

Structure

StructureThis is a conveyor having a squared log coiled in a spring shape which is rotated to transport chips. There are a flat transportation type and an end section pushing up type.

Features

For flat transportation, almost everything but viscous chips such as long and thin chips from stainless steel can be transported. Depending on the quantity and hardness of chips, a coil lineshape should be chosen.In the case of the end section pushing up type, sandy chips cannot be pushed up. If the chip material is hard, the coil end would be defeated by chips and wear thin. However, general chips can be carried. The advantage of the end section pushing up transport is that chips are packed, less bulky and better at draining after they are discharged.

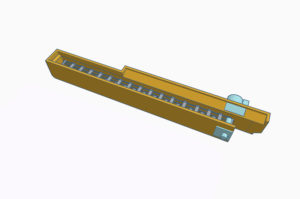

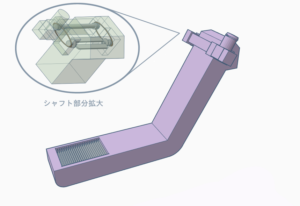

Screw Conveyor

Structure

StructureHelical flat steel is wrapped around pipe and welded. This works in the same manner as a coil conveyor.

Features

This is used for hard chips, which are unfitted for a coil conveyor. Especially, the end section pushing up type is more often chosen by customers because it well compresses the discharged chips and well drains off the coolant solution.

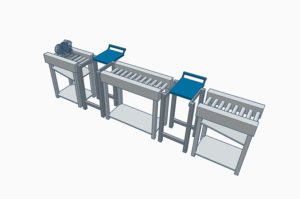

Collecting Conveyor

Structure

StructureChips discharged from plural machines and coolant are transported in a concentrated manner to allow for controlling the discharge of all chips in the plant.

Features

A combination of conveyors suitable for various chips will be fully customized and designed.

Work Conveying Machine

Structure

StructureA conveyor that fits each work shape and transporting function will be specifically designed and manufactured.

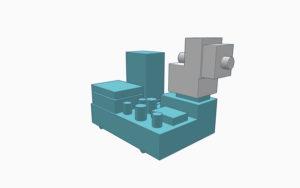

Coolant Tank

Structure

StructureWithout using a chip conveyor, coolant solution is filtered by a receiving basket and precipitation effect.

* Careful consideration is required for selection of a conveyor. Please consult with us.